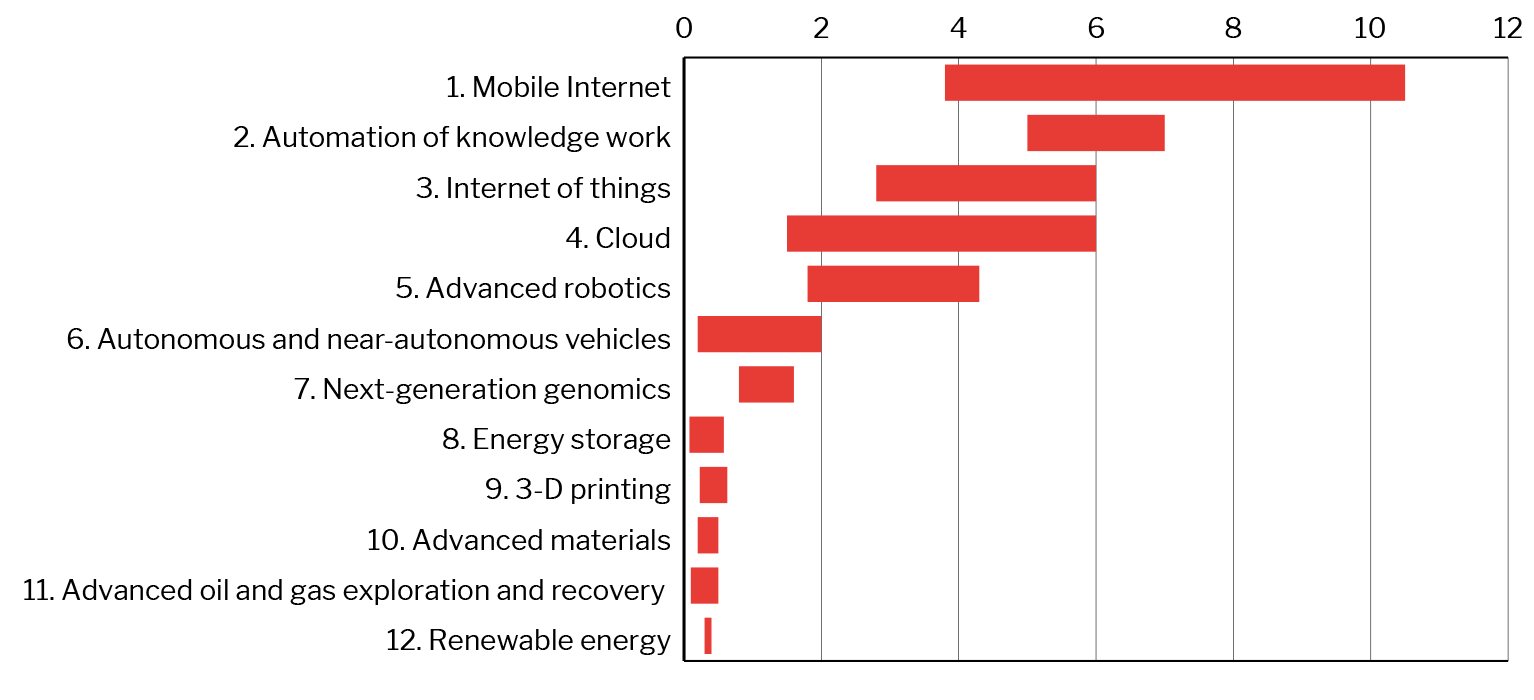

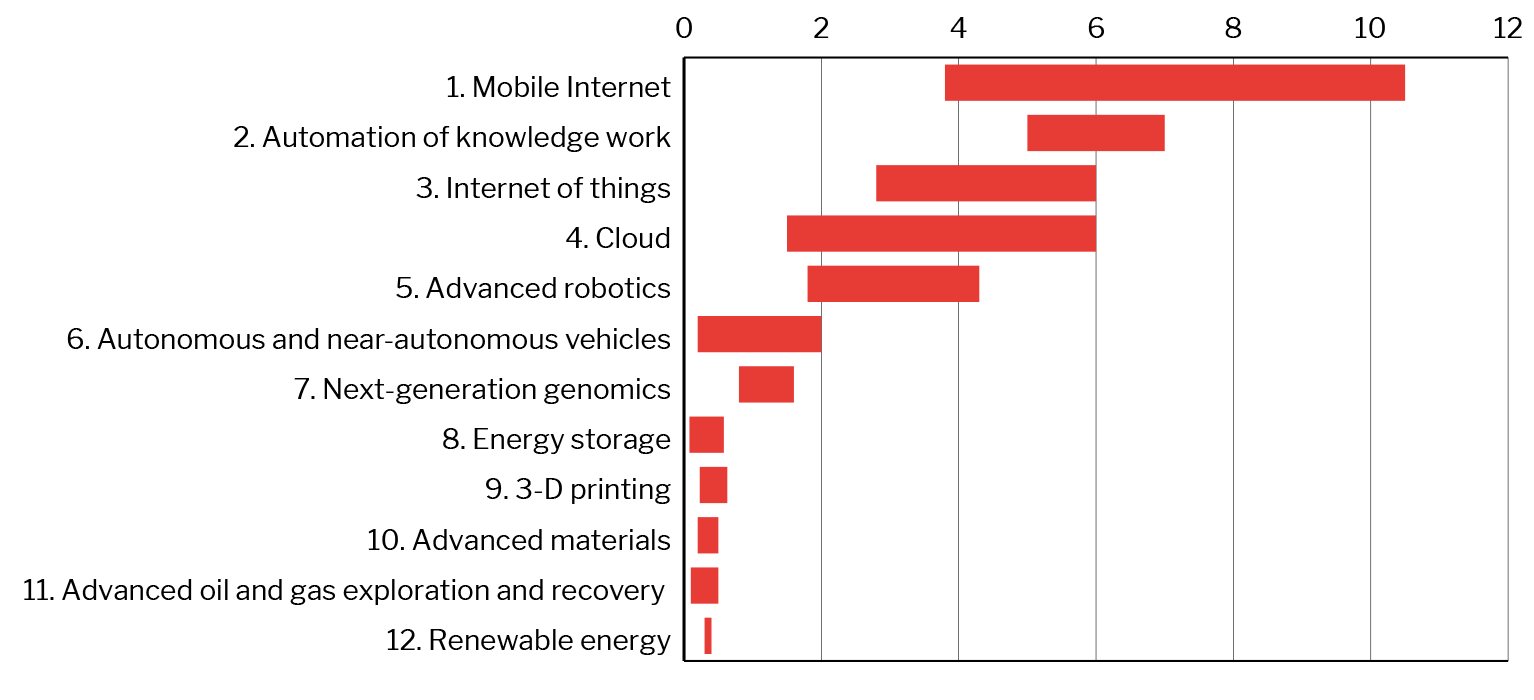

Estimated potential economic impact of technologies across sized applications in 2025, $ trillion annual

The impact of connectivity and digitalisation can be felt everywhere. In this article we look at Industry 4.0, the effect it’s having on manufacturing and the sales process, and why designing for Industry 4.0 is essential moving forward.

Manufacturing as we know it is changing. As we enter the fourth industrial revolution – Industry 4.0 the production process will never be the same again. The Internet of Things (IoT) machine learning, cloud computing and autonomous production lines, are all part of the new manufacturing reality. Advances in connectivity are also impacting the way products are sold as manufacturers tear up tradition revenue models and adopt software as a service (SAAS) pricing.

Mining companies no longer buy drilling equipment, but rather pay per meter drilled, jet engines are paid for per hour of flight rather than being purchased outright. Gas plants, often in remote areas, use thousands of sensors to register and analyze real-time data in order to flag problems before they become a major issue. To be able to offer this type of service, manufacturers must monitor a consistent stream of data to ensure their products are always running efficiently. Service has to be designed into products from day one.

Industry 4.0 will turn traditional linear production on its head, as linear supply chains give way to a more dynamic set-up. McKinsey estimates the economic impact of IoT and cloud services in USD trillions.

Data, and the ability to capture, filter and analyse it, is business critical. Forrester estimates that 60-73% of data goes unused by businesses, but in a world with so much of it, knowing which data to use and which to filter out (securely) is key to gaining a competitive advantage.

Researchers at Dortmund University define IoT as “’things’ and ‘objects’” (such as radio-frequency identification (RFID), sensors, actuators and mobile phones) “which interact with each other and cooperate with their neighbouring ‘smart’ components to reach common goals”. Via IoS (Internet of Services), both internal and cross-organisational services are offered and utilised by participants of the value chain. The IoT ‘things and objects’, can be integrated with other technologies such as machine learning, augmented (artificial) intelligence and blockchains, depending on the value and relevance each component adds to the specific context.

The concept of “Just In Time” management has been in use for many years, whereby parts are delivered to the production line as they are needed. The digital factory embraces this thinking but also supports order changes and even design changes during production. Smart production can inform the production line to prepare for product changes as products move through production, with a minimum of downtime. The factory runs smoothly, with no paper trail and minimum input from humans. Those staff working on the shop floor are trained to follow instructions from smart devices around the plant. Service is minimised as predictive software can determine when production line maintenance is required and production flow can be tailored to incorporate it, with minimum impact. Additionally, things like lighting and heating of the factory premises automatically adjust or turn on and off, in order to provide the best working environment and save energy. One company that is at the forefont of this is Fujitsu at its computer production and hardware plant in Germany.

Jeff Gothelf, co-author of the book on learning cultures within organisations, refers to this as “sense and respond” in the book of the same name. Companies can now capture a wealth of data, and respond appropriately. An example in case happened at Tesla when a customer got fed up with other Tesla drivers leaving their cars in the public superchargers for hours on end. He tweeted his discontent to Elon Musk who answered him not long after “You’re right. this is becoming an issue. Supercharger spots are meant for charging, not parking. Will take action.” Six days later an update to Tesla cars was launched. Now Tesla owners receive a push notification when their cars are fully charged, informing them that a parking fee will be charged shortly if they do not unplug from a public charger. Elon Musk did not only respond this way because he felt it was the right thing to do – he responded because he had the data backing up the story, namely that people use the supercharger stations as parking lots. The solution with the push notice might not be the optimal one, but at least Tesla had the capability to respond quickly. They launched a minimum viable solution that they can test, gather data, and then take it from there.

Right now, there is anything between 10 and 25 billion IoT connected devices – depending on which source you read. Experts may disagree on the actual figure, but what they do agree on is the growth rate of billions year on year indefinitely. This is having a game-changing impact on the way industrial products are bought and sold. The IT sales models of Software As A Service (SAAS) and Infrastructure As A Service (IAAS) are now being demanded by procurers of industrial products. Product As A Service (PAAS) is becoming the new way to purchase, and IoT – and the data it relays back to manufacturers – is enabling manufacturers to provide this service effectively. Rolls Royce is a pioneer in this field. The company offers “power-by-the-hour”, an accessory and engine replacement service that was started way back in 1962. In 2002 they added “CorporateCare” as an additional service. With sensors pro-actively predicting maintenance requirements for the engines and a lease plan for engines during plane maintenance – Rolls Royce can offer proactive engine rental services. This allows customers to focus on their core businesses and reduces their risk. The sensors aren’t only used once a product is delivered, they are also put to use in the manufacturing phase to monitor their progress as they move through the production line.

Rolls Royce offers “power-by-the-hour”, an accessory and engine replacement service that was started way back in 1962. In 2002 they added “CorporateCare” as an additional service. With sensors pro-actively predicting maintenance requirements for the engines and a lease plan for engines during plane maintenance – Rolls Royce can offer proactive engine rental services.

Many other manufacturers have adopted similar processes. The power tools manufacturer, Hilti, launched “ONTrack” for their customers, so they could gain an immediate overview of what equipment they have, while a Bluetooth tagging system supports streamlined inventory lists. Basically, they add an organisational layer for tools, which enables customers to focus on getting the job done more efficiently. In the highly regulated food industry, suppliers invest in blockchains to increase transparency in the supply chain of raw ingredients, to avoid more meat scandals and the like. This enables them to fault-find quicker and avoid costly recalls – and sick customers! My former employer Airbus works with IBM’s Watson to collect info from sensors on the factory floor. According to Simon Bradley, VP Product and Cyber Security, Airbus. “One of the first things the company did was to use RFID to track parts. Now we’re moving towards IoT devices to track power tools in the factory, so technicians know where their tools are. The tools can also inform technicians if they need to be serviced of if the torque is correct in preparation for use.”

“We are deluding ourselves if we think that the products we design are the ‘things’ that we sell, rather than individual, social and cultural experience that they engender, and the value and impact they have,” says Bill Buxton, Microsoft Principal Researcher and ’evangelist’. What he’s alluding to here is design. All the technology in the world won’t help you if you haven’t considered the user’s needs. Technology has to be designed into manufacturing and it has to be designed into products to deliver the best results for the user. At Daresay we always begin from the user perspective and work back to the product or service being offered. By marrying a user and a service (or PAAS) through technology we ensure all aspects of the value chain are incorporated into a solution. We map the challenges – from the context of our customers – from both design and tech perspectives. And we build and test prototypes – moving through productive failures before delivering effective results. Eric Ries, author of “the lean startup” calls it “productive failures” – whereby you try things out, learn something, and then adjust, and fail less, and less, in iterative agile cycles. This type of thinking is essential to avoid becoming the new Kodak or Blackberry; companies that failed to react in time to the changing business landscape. The prototype is never an “end” product but is a prototype that leaves enough ‘holes’ in it for the imagination to fill in the missing parts and the next steps.